Silica gels adsorb moisture & protect equipment and products from moisture damage

High adsorption capacity up to 37% / 90%

With harmless color indicators

Can be used at temperatures up to 100°C

Can be used at humidity levels above 10% RH

Regenerable from 120°C

Silicagel besteht aus Kieselsäure - genauer gesagt Siliciumdioxid (SiO₂). Das ist eine chemische Verbindung aus Silizium und Sauerstoff, die sowohl natürlich als auch synthetisch vorkommt. Es ist ein chemisch stabiles und inertes Material, das in vielen industriellen und technischen Anwendungen als effektives Trockenmittel eingesetzt wird. Kieselsäure selbst ist amorph, das heißt seine Atome sind in keinem regelmäßig wiederkehrenden Muster angeordnet. Dadurch entsteht eine sehr poröse Struktur mit tausenden winzigen Poren, die eine extrem große Oberfläche von bis zu 800 m² pro Gramm Silicagel bilden. Zudem ist die Oberfläche durch die innere Atomstruktur polar und unterschiedlich geladen. So können Wasserstoffmoleküle aktiv angezogen werden - rein physikalisch. Diese spezielle Oberfläche macht Silicagel besonders effektiv darin, Feuchtigkeit und andere Moleküle aus der Umgebungsluft aufzunehmen.

Die Trockenperlen gibt es in verschiedenen Körnungen, üblicherweise zwischen 1,0 und 5,0mm - meist abhängig vom spezifischen Anwendungsfall. In einigen Anwendungen werden zudem Farbindikatoren beigemischt, die eine einfache visuelle Kontrolle ermöglichen: Sie zeigen an, wann das Silicagel gesättigt ist und keine weitere Feuchtigkeit mehr aufnehmen kann.

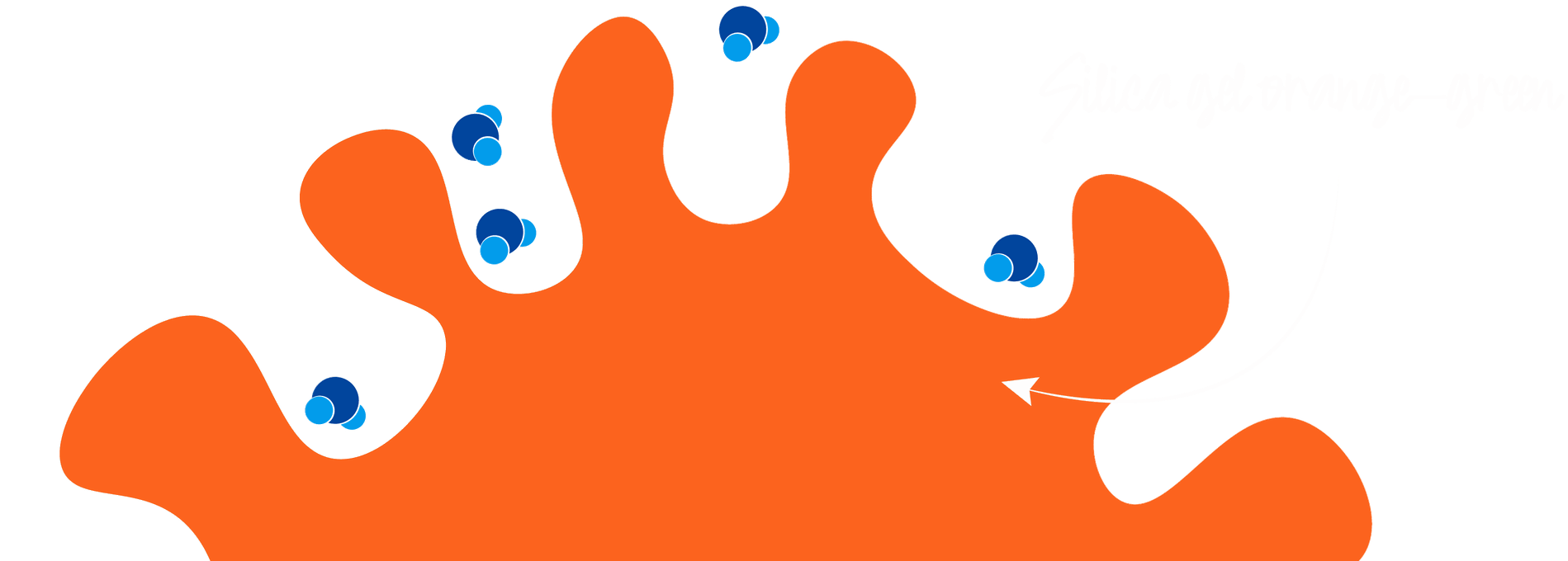

Um die Funktionsweise von Silicagel zu verstehen, muss zuerst der Unterschied zwischen Adsorption und Absorption verstanden werden. Bei der Adsorption lagern sich Moleküle - in diesem Fall z.B. Wasserdampf an der Oberfläche der Poren an. Das Ganze ist ein rein physikalischer Prozess, ohne dass dabei chemische Bindungen eingegangen werden. Bei der Absorption dagegen dringen Moleküle in das Innere eines Materials ein. Silicagel arbeite primär mit der physikalischen Adsorption, wodurch es in der Folge auch wieder regenerierbar ist.

Die Regeneration erfolgt durch Erwärmen der Trockenperlen, wodurch die adsorbierte Feuchtigkeit an der Oberfläche wieder freigesetzt und das Material getrocknet wird. Die physikalischen Kräfte wie die van-der-Waals-Kräfte oder Wasserstoffbrückenbindungen, die die Wassermoleküle an der Oberfläche halten, werden durch die Wärmezufuhr überwunden. So kann Silicagel mehrfach genutzt werden, ohne dass seine Adsorptionsfähigkeit verloren geht.

Besonders hervorzuheben ist zudem die chemische Inertheit und Stabilität von Kieselsäure bzw. Silicagel. Es reagiert nur sehr selten mit anderen Materialien, greift keine Oberflächen an und kann dennoch extrem effektiv Luftfeuchtigkeit aufnehmen. Alles dank einer Kombination aus hoher Porösität, der großen inneren Oberfläche und der polarisierten Struktur der Kieselsäure, die Wassermoleküle aktiv anzieht.

Water vapor is present in all ambient air—even if we can't see it. This invisible moisture can cause significant damage to products.

The highly porous structure gives the drying beads an enormously large surface area. These pores physically attract water molecules and bind them to their surface – completely without the addition of chemicals.

The bound moisture remains bound inside the granules and the humidity in the surrounding air can be successfully reduced.

Many silica gel variants indicate when they are saturated and can no longer absorb water by changing color—for example, from orange to green. At this point, the drying beads should either be replaced or permanently regenerated.

Warum ist PORESPHERE Silicagel ein hervorragendes Trockenmittel?

1. High water absorption

Silica gels are capable of storing up to 40% of their own weight in water. This is facilitated by their strong affinity to dipole molecules, a porous structure, and a large internal surface area.

4. Color indicator

Silica gels can be provided with a color indicator that changes color to indicate when the maximum water absorption capacity has been reached.

Ungiftig & chemisch inert

PORESPHERE Silicagele sind ungiftig, chemisch inert und gegen nahezu alle Säuren beständig. Sie sind damit auch für den Einsatz in der Lebensmittelindustrie und Pharmazie geeignet.

2. Regenerable

Water molecules are attached to the silicon dioxide by what are known as Van der Waals forces. This physical process is reversible. When silica gel is heated to over 120°C, the water molecules are released again.

Wo wird PORESPHERE Silicagel eingesetzt?

examples:

Transformators

Silica gel is used in transformer breathing apparatus to dry incoming air before it comes into contact with the insulating oil.

This keeps the moisture content in the oil consistently low – this protects the insulation, prevents internal corrosion and extends the service life of the transformer.

Prevents condensation

Maintains the dielectric strength of the insulating oil

Protection against corrosion and arc discharge

Extends maintenance intervals and service life

Packaging

In packaging, silica gel protects sensitive products such as electronics, leather goods, textiles or optical devices from moisture damage.

It specifically prevents the formation of mold, corrosion, or odors during storage and shipping, thus helping to avoid complaints due to transport damage.

Protection against mold, rust, decomposition and odor formation

No complaints due to moisture damage

Various formats for every packaging size

Humidity indicator for visual inspection

Industry

In industrial applications, silica gel is used wherever machines, components or controls in closed housings need to be protected from humidity.

It prevents the formation of condensation, protects electronics and mechanics and thus reduces the risk of failures and repairs.

Avoiding short circuits caused by condensate

Protection of electronic and mechanical components

Prevents corrosion in closed systems

Lower failure rates

Pharma

Silica gel is used in the pharmaceutical industry, among other things, to keep sensitive preparations dry – for example in blister packs, tubes or diagnostic kits.

It prevents active ingredients from degrading due to moisture, ensures stable storage conditions and contributes to consistent product quality.

Prevents active ingredient degradation due to moisture

Extends shelf life and stability of preparations

FDA and EU compliant products

Maintains consistent quality of pharmaceutical products

PORESPHERE™ A vs. Makro - Was ist der Unterschied?

Engporige (Typ A) vs. weitporige Silicagele.

PORESPHERE A (Typ A Engporig)

2-4nm pore diameter

Für niedrige Luftfeuchtigkeit Umgebungen

Dehumidify already dry air even further

Ggf. mit Sättigungsindikator (Grün oder Farblos)

PORESPHERE Makro B (Weitporig Typ B)

6-12nm pore diameter

Für hohe Luftfeuchtigkeit Umgebungen

Nehmen schnell, viel Wasser in feuchter Luft auf

Nicht geeignet für präzise Trocknung von Restfeuchte

Bei unseren PORESPHERE™ A Produkten handelt es sich um engporige Silicagele vom Typ A. Diese haben kleinere Poren mit einem Durchmesser von 2-4nm, während weitporige Silicagele (PORESPHERE™ Makro) größere Poren mit einem Durchmesser von 6-12nm haben. Hierdurch ergeben sich unterschiedliche Adsorptionseigenschaften:

Engporige Typ A Sorten glänzen mit ihren Adsorptionseigenschaften bei niedrigen Luftfeuchten und sind deshalb ideal, wenn in bereits trockenen Umgebungen die Luft noch weiter entfeuchtet werden muss - für eine effektive Trocknung.

Weitporige Silicagele entfalten ihr Potenzial hingegen bei hohen Luftfeuchten, wenn viel Wasser schnell aufgenommen werden muss. Dafür stoßen sie an ihre Grenzen, wenn es darum geht die letzte Restfeuchte in der Umgebungsluft präzise zu trocknen.

*Aufgepasst bei den Bezeichnungen für Sillicagele: Engporige Trockenperlen werden in der Regel immer als Typ A klassifiziert. Weitporige Trockenperlen sind dagegen nicht immer automatisch vom Typ B, da die Kategorie "Weitporig" selbst meist nochmals in die Typen A,B und C unterkategorisiert ist. Es gibt also bspw. auch weitporige Silicagele vom Typ A und vom Typ C.

What color indicators exist?

Unser PORESPHERE™ A gibt es klassisch als weiße, farblose Perlen, aber auch mit Indikator in den Varianten Grün oder Farblos. Dieser zeigt zuverlässig an, wann das Trockenmittel seinen Sättigungszustand erreicht hat und ausgetauscht oder regeneriert werden muss:

| Color Indicator |

Color Change from ... to ... |

Availability | Safety | PORESPHERE™ A |

Copper(II) sulfate (copper salt) | Orange - Grün (PORESPHERE A Indikator OG) | Yes | Harmless | |

Iron(III) chloride (iron salt) | Orange - Farblos (PORESPHERE A Indikator OF) | Yes | Harmless | |

Cobalt(II) chloride (heavy metal) | blue - pink | No | No, carcinogenic SVHC substance | - |

Downloads.

Was steckt hinter unseren PORESPHERE Alumina Trockenperlen?

Unsere Alumina-Trockenperlen kombinieren die hohe Adsorptionsleistung klassischer Silicagele mit der zusätzlichen Stabilität von Aluminiumoxid. Sie eignen sich ideal für anspruchsvolle Trocknungsprozesse, bei denen Temperaturwechsel, hohe Feuchtelasten oder chemische Beständigkeit gefordert sind. Durch ihre kugelförmige Struktur und optimierte Porengrößenverteilung gewährleisten sie maximale Effizienz und gleichmäßigen Luftdurchfluss.

In unserem Sortiment bieten wir drei verschiedene Alumina Varianten an. Unser AL-W kennzeichnet sich durch ein klares Alleinstellungsmerkmal: Es ist resistent gegen flüssiges Wasser und behält auch während direktem Kontakt seine Struktur und Adsorptionseigenschften bei. Das AL-N ist sozusagen die Basis-Variante der Alumina Reihe: Stabil, belastbar und optimale Adsorptionseigenschaften. Beim AL-H handelt es sich zum Schluss um ein noch besser optimiertes Silicagel, dass für sehr spezifische Einsatzgebiete entwickelt wurde, wo das AL-N an seine Grenzen stößt.

AL-W (wasserresistent)

Resistant to liquid water

Good adsorption properties in the presence of moisture

Regenerable

AL-H (high performance)

Temperature resistance combined with high adsorption performance

Stable under thermal stress and strain

Flexible to use in various conditionsFlexibel einsetzbar in verschiedenen Bedingungen

AL-N

Structurally stable, even under prolonged stress

Has a basic surface

Absorption of acidic components and polar molecules

Körnungen - Welche ist wann geeignet?

Ein wichtiger Faktor für die Leistungsfähigkeit von Silicagel ist die Körnung, also die Größe der einzelnen Silicagel-Kugeln. Diese bestimmt, wie schnell Moleküle wie Wasserdampf in die Poren eindringen können und wie stark Luft- oder Gasströme durch das Schüttbett im Filter gebremst werden.

Entscheidend dafür sind die sogenannten Diffusionswege: Damit ist der Weg gemeint, den ein Molekül zurücklegen muss, bis es im Inneren einer Silicagel-Kugel die Poren erreicht und dort adsorbiert werden kann. Je kleiner die Kugeln, desto kürzer der Diffusionsweg – und desto schneller erfolgt die Adsorption.

Feine Silicagel-Körnungen:

... haben eine größere Oberfläche pro Volumen, was eine besonders schnelle Adsorption von Feuchtigkeit ermöglicht.

Durch die kurzen Diffusionswege können Wassermoleküle sehr schnell gebunden werden. Ein Nachteil ist jedoch der höhere Druckverlust: Da die Zwischenräume zwischen den kleinen Kügelchen enger sind, wird ein Gas- oder Luftstrom stärker gebremst.

Deshalb eignet sich diese Körnung vor allem für kleine Volumen und schnelle Trocknungsvorgänge, beispielsweise in Trockenmittelbeuteln für Elektronik, Pharma oder Lebensmittel.

Die mittlere Körnung

... stellt den optimalen Kompromiss dar. Hier verbinden sich eine effiziente Adsorptionsgeschwindigkeit mit einem moderaten Druckverlust, sodass sie universell einsetzbar ist.

Sie wird besonders häufig in Drucklufttrocknern, Transformatoren und Gaskreisläufen verwendet, da sie sowohl bei kleineren als auch bei größeren Volumenströmen zuverlässig arbeitet.

Gröbere Silicagel-Körnungen

... zeichnen sich durch einen sehr geringen Druckverlust aus, da die Zwischenräume zwischen den Kugeln deutlich größer sind. Das macht sie ideal für hohe Volumenströme und großvolumige Adsorberanlagen, wie etwa in der Biogasaufbereitung oder industriellen Gastrocknung.

Allerdings ist der Diffusionsweg länger, sodass die Adsorption mehr Zeit benötigt.

Damit das Silicagel seine volle Leistung entfalten kann, ist eine ausreichende Kontaktzeit zwischen Gas und Adsorbermaterial entscheidend.

Was muss ich über die Regeneration von Silicaperlen wissen?

Kieselsäure Perlen binden Wasserdampf physikalisch durch Adsorption an ihrer großen inneren Oberfläche. Diese Bindung ist nicht chemisch, sondern kommt durch Wasserstoffbrücken und Van-der-Waals-Kräfte zustande. Deshalb kann dieser physikalische Effekt typischerweise durch Erwärmung wieder rückgängig gemacht werden. Die Trockenperlen werden dabei durch Erwärmung getrocknet und können wieder frisch eingesetzt werden.

Unsere PORESPHERE™ Silicagele können bei einer Temperatur von 120-140°C regeneriert werden (genaue Temperaturangaben sind in den Datenblättern vorhanden). Dabei muss das Granulat über mehrere Stunden konstant erwärmt werden. Temperaturen unterhalb von 100°C reichen nicht aus, um die Trockenperlen vollständig zu regenerieren, während Temperaturen über 180°C die Struktur der Poren beschädigen können, speziell bei Silicagelen mit Farbindikator.

Passende Silicagele für Ihre Anwendung.

PORESPHERE A Indikator OG

With harmless color indicator

Color change at 10-20% load

High adsorption capacity (35%)

- Structure 99% SiO2 1% copper(II) chloride

- Grain Size 3-5mm

- Water absorption >370ml/kg

- Bulk density 0,78g/ml

- Pore volume 0,35-0,45ml/g

- Breakage resistance >200N

- Specific surface area 600-800qm/g

- Abrasion rate <2%

- Regeneration at 120°C

PORESPHERE A Indikator OF

With harmless color indicator

Color change at 20-25% load

High adsorption capacity (35%)

- Structure 99% SiO2 1% ammonium iron (III) sulfate

- Grain Size 3-5mm

- Water absorption >370ml/kg

- Bulk density 0,78g/ml

- Pore volume 0,35-0,45ml/g

- Breakage resistance >200N

- Specific surface area 600-800qm/g

- Abrasion rate <2%

- Regeneration at 120°C

PORESPHERE A Weiß

Without color indicator

High adsorption capacity (35%)

- Structure 99% SiO2

- Grain Size 0,5-1,5mm, 1-3mm, 2-5mm

- Water absorption >370ml/kg

- Bulk density 0,77g/ml

- Pore volume 0,35-0,45ml/g

- Breakage resistance >200N

- Specific surface area Oberfläche 650-800qm/g

- Abrasion rate <2%

- Regeneration at 140°C

PORESPHERE Makro B

Without color indicator

Very high adsorption capacity (90%)

- Structure 99% SiO2

- Grain Size 2-5mm

- Water absorption >900ml/kg

- Bulk density 0,85kg/l

- Pore volume 0,85-1,00ml/g

- Breakage resistance >200N

- Specific surface area 550-650qm/g

- Abrasion rate <1%

- Regeneration at 140°C

PORESPHERE AL-W (wasserresistent)

Without color indicator

Also adsorbs liquid water

High adsorption capacity (35%)

- Structure 86.5% SiO2 13.5% Al2O3

- Grain Size 3-5mm

- Buld density 0,749g/ml

- Pore volume 0,42ml/g

- Breakage resistance >70N

- Specific surface area 350-450qm/g

- Abrasion rate 0,03%

- Regeneration at 140°C

PORESPHERE AL-N

Without color indicator

High adsorption capacity (35%)

- Structure 97% SiO2 3% Al2O3

- Grain Size 3-5mm

- Bulk density 0,80g/ml

- Pore volume 0,40ml/g

- Breakage resistance >180N

- Specific surface area 750qm/g

- Regeneration at 140°C

PORESPHERE AL-H

Without color indicator

Hohe Adsorptionsfähigkeit (35%)

- Structure 96.6% SiO2 3.4% Al2O3

- Grain Size 3-5mm

- Bulk density 0,725g/ml

- Pore volume 0,49ml/g

- Breakage resistance >211N

- Specific surface area 729qm/g

- Abrasion rate 0,01%

- Regeneration at 140°C

Downloads.

Silica gel | Technisches Datenblatt (TDB) und Sicherheitsdatenblatt (SDB) |

| PORESPHERE A Indikator OG Typ: A, (engporig) (orange - grün) | DOWNLOAD |

| PORESPHERE A Indikator OF Typ: A, (engporig) (orange - farblos) | DOWNLOAD |

PORESPHERE A Weiss | |

PORESPHERE Makro B | |

PORESPHERE AL-W | |

PORESPHERE AL-N | |

| PORESPHERE™ AL-H Alumina Gel-H (high performing) |

FAQ about Silica gels.

Features

There are different types of silica gel which differ in their chemical composition, color, and intended use. Basically, silica gel is an amorphous, highly porous silicon dioxide (SiO₂) that is capable of adsorbing large amounts of moisture from the ambient air.

Silica gel is available in various forms: colorless (indicator-free), color-changing (with a moisture indicator), and specialized forms with varying pore structures or additional functionality. The choice of the right silica gel depends on the specific application: whether for moisture protection in packaging, for protecting electronics, or for industrial drying. Our company offers all common silica gel types, individually tailored to your needs.

The effectiveness of silica gel depends largely on the ambient conditions, humidity, temperature, and the amount of material used. In typical packaging or storage applications, high-quality silica gel can adsorb moisture for 4 to 12 weeks at normal humidity (40–60% RH) before reaching saturation. In dry environments, it can even remain active for many months.

Silica gel is often impregnated with color indicators to visualize the saturation level reached. The color change is usually from orange to dark green, providing high contrast and reliably indicating when the material has reached its capacity. Silica gel is also available with other color indicators, such as orange to white and blue to pink.

Silica gels without color indicators are also available. However, indicator-free silica gel must be replaced regularly or monitored using alternative methods.

Yes, saturated silica gel can be regenerated and reused multiple times through proper heating. Thermal regeneration reliably restores its adsorption capacity. High-quality silica gel can withstand numerous drying cycles and remains effective if properly treated. For product variants with a color indicator, the color returns after drying and once again indicates the saturation level.

The silica gel is spread out on a baking sheet and dried in a standard oven at 120°C (depending on the type of silica) for approximately five hours. Higher temperatures should be avoided to avoid damaging the material. It is recommended to repeat this process a maximum of five times before replacing the silica gel completely.

So-called self-regeneration is also possible. In this process, the already dried air flushes the water out of the material during the cyclic breathing of a container or system as exhaust air. This partially discharges the desiccant without external heat input or pressure changes, significantly extending its service life.

The maximum moisture absorption of silica gel is up to 37% of its own weight. This means that 1 kg of dry silica gel can adsorb up to 370 g of water vapor from the air under optimal conditions.

These values depend on the relative humidity, the ambient temperature, the pore structure and grain size of the desiccant, and the material quality. Silica gel works particularly efficiently at high humidity levels. This absorption capacity makes silica gel one of the most effective and versatile desiccants for industrial, technical, and residential humidity control applications.

To maintain its maximum adsorption capacity, silica gel must be stored in a dry, airtight container, and protected from environmental influences. Silica gel begins to absorb moisture immediately upon exposure to ambient air—even at relatively low humidity. Therefore, proper storage is crucial for long-term functionality. Sealed, moisture-proof containers or packaging are ideal. Opened containers should be used promptly or resealed airtight. If stored improperly, the material may become saturated with moisture before its intended use and should then be regenerated first.

The term "self-regeneration" of silica gel refers to the material's ability to restore part of its adsorption capacity independently under certain conditions—that is, without targeted technical regeneration such as heating in an oven. In practice, this form of "self-drying" is often observed when environmental conditions change significantly, especially during fluctuations in temperature or humidity.

Silica gel physically binds moisture in its porous structure (adsorption). Unlike chemical bonds, this adsorption is reversible—meaning the moisture can be released again. This occurs when humidity drops significantly, but also when ambient temperatures increase. This passive drying process is called self-regeneration, but it is only partially effective. It does not release the full amount of bound water, but can almost double the potential service life before the material becomes fully saturated.Silicagel bindet Feuchtigkeit physikalisch in seiner porösen Struktur (Adsorption). Anders als chemische Bindungen ist diese Adsorption reversibel – das heißt, die Feuchtigkeit kann auch wieder abgegeben werden. Dies geschieht bei stark sinkender Luftfeuchtigkeit aber auch bei Erwärmung durch Umgebungseinflüsse. Diese passive Rücktrocknung wird als Eigenregeneration bezeichnet, ist aber nur teilweise wirksam. Sie gibt nicht die volle gebundene Wassermenge ab, kann aber die mögliche Nutzungsdauer vor einer vollen Sättigung des Materials fast verdoppeln.

However, to restore the full moisture absorption capacity, targeted thermal regeneration in the furnace is required. This completely removes the adsorbed water from the pores of the silica gel, allowing it to function like new again.

Color indicators in silica gel are used to visually detect moisture content—that is, whether the silica gel is still active or already saturated and no longer capable of adsorption. These indicators are chemical additives that change color visibly depending on the moisture content, allowing for quick and easy monitoring—without the need for technical measuring devices.

Silica gel itself is colorless or white. To visualize the saturation state, small amounts of organic color indicators are added to the material. Due to their nature as weak acids or bases, these indicators react with water in chemical-physical reactions. As the water content in the material increases, the pH value increases, and the color changes, for example, from orange to green or white.

This process is reversible and can be repeated. Heating removes the moisture, and the color indicator returns to its original color due to the lack of water.

Fiel of Application

The choice between narrow-pore and wide-pore silica gel—also referred to as Type A and Type B/C—depends largely on the relative humidity, the desired adsorption performance, and the intended use. Both types differ in the size of their pore structure and thus in their ability to absorb water vapor at different humidity levels.

Narrow-pore silica gel (Type A) is particularly suitable for low humidity and precise humidity control, for example in electronics, medicine or laboratory applications.

Wide-pore silica gel (type B or C) is preferably used in high or changing humidity conditions, for example in packaging, logistics or in the presence of organic vapors.Weitporiges Silicagel (Typ B oder C) wird bevorzugt bei hoher oder wechselnder Luftfeuchte, etwa in Verpackungen, Logistik oder bei organischen Dämpfen eingesetzt.

The choice of pore size significantly influences the efficiency and service life of the desiccant – the appropriate silica gel should be selected specifically for the application. In complex applications, a mixture of both types may also be useful, e.g., for short-term adsorption (Type B) and ultra-fine drying (Type A).

Narrow-pore types are used, for example, to protect sensitive electronics, effectively absorbing even very low levels of residual moisture. Wide-pore types, on the other hand, are ideal for packaging with highly fluctuating humidity levels, as they remain functional despite these changes.

The key difference between silica gel with indicators and silica gel without indicators lies in the ability to visually monitor moisture levels. While both variants can adsorb moisture equally effectively, only silica gel with a color indicator allows for visible detection of the saturation level—which is crucial in many applications.

The ambient temperature has a direct influence on the effectiveness of silica gel in adsorbing moisture. Generally speaking, the higher the temperature, the lower the adsorption capacity – and vice versa. This effect can be explained physically and should always be taken into account when selecting and planning drying solutions. While silica gel is very effective at 20°C, its adsorption capacity can decrease significantly at 40°C or higher. Therefore, in hot environments, the amount used should be adjusted, the packaging optimized, or regeneration performed more frequently.

If the temperature of the incoming air rises beyond this limit, the use of molecular sieves or mixtures containing molecular sieves is recommended instead. These offer excellent water vapor absorption capacity even at temperatures well above 40°C. Their ventilation drying ability remains more consistent over a wider temperature range than silica gel.

The selection of the appropriate silica gel depends crucially on the ambient humidity level. Relative humidity (RH) is particularly relevant – that is, the proportion of water vapor in the air relative to the maximum possible humidity at a given temperature.

The pore size of the silica gel is crucial for its appropriate use. This determines how well water molecules can be bound at different humidity levels. The following generally applies:

Weite Poren (Typ B)(Poresphere Makro B) = besser bei viel Wasserdampf für effiziente Adsorption

Narrow pores (Type A) = better with little water vapor and as little residual moisture as possible

Yes, silica gel can be safely used in food packaging, provided it is specifically approved and certified for this purpose. In its pure, indicator-free form, silica gel is a chemically inert, non-toxic desiccant that does not react with food and is therefore food-safe—provided it meets certain regulatory requirements.

It must be:

- indicator-free (white/colorless), be approved under food law

- approved under food law, e.g. according to: EU Regulation (EC) No. 1935/2004 or FDA standard (21 CFR 182.2420) in the USA

- protected from direct contact in suitable packaging

Silica gel can be safely used in food packaging – provided it is indicator-free, certified food-safe, and correctly packaged. Pure, white silica gel without colorants is considered harmless to health and reliably protects food from moisture damage such as mold, spoilage, or loss of quality. Silica gel containing color indicators, on the other hand, is not food-safe and must not come into contact with food.

A ventilation dryer—also known as an air dryer or dehumidifier—is a technical unit that removes moisture from flowing air before it enters sensitive systems or components. This is crucial, for example, in compressed air systems, transformers, hydraulic systems, storage tanks, control cabinets, and even battery compartments.

Silica gel is so widely used in these applications because it is an extremely powerful, versatile, and regenerable desiccant that can efficiently adsorb water vapor, especially in air-conditioning systems – even at low temperatures and fluctuating humidity levels. It can adsorb large amounts of moisture from the air, protects sensitive systems from condensation and corrosion, and operates reliably even under constantly changing environmental conditions. This makes silica gel the preferred desiccant in industrial air-drying applications, transformers, compressed air systems, and other air-conditioning processes.

Safe Use

Yes, in its pure form, silica gel is safe and non-toxic to handle, both for humans and for most materials and products. It is a chemically inert, amorphous silicon dioxide (SiO₂) that does not emit toxic fumes, is non-reactive, and non-flammable. However, there are important differences between different silica gel variants that must be considered when assessing safety.

Many products contain color additives to visualize saturation. These indicators can contain hazardous substances, such as cobalt(II) chloride in blue. This substance is proven to be carcinogenic and toxic to fertility. Orange/green-based indicators are a safe alternative. However, these should not be swallowed or brought into contact with food.

According to European Union legislation, pure silica gel, molecular sieves, and aluminum oxide are not classified as hazardous. Therefore, if handled and used properly, no environmental problems are to be expected.

Silica gel is often colored with specific dyes that serve as indicators. Their color indicates when the material is saturated and can no longer absorb any more moisture. This provides guidance as to when the silica gel needs to be replaced or regenerated.

Blue silica gel contains hazardous cobalt(II) chloride and carries, among other things, the warning R49 - "may cause cancer by inhalation" - and is also teratogenic. Inhaling the dust, which contains heavy metals, should therefore be avoided at all costs. This dust can escape and enter the environment, especially when transferring the material or even when packaging bags are damaged slightly. On October 28, 2008, the ECHA (European Chemicals Agency) re-added the substance to the candidate list of substances of very high concern (SVHC). The entry was supplemented on June 20, 2011, to include reproductive toxicity.

Orange silica gel, on the other hand, uses other substances as a color indicator and is therefore considered harmless and non-toxic to humans and the environment, making it a safer alternative. White or colorless silica gel is equally safe and non-toxic to handle due to the lack of a color indicator.

Silica gel is subject to specific safety standards, norms, and legal requirements depending on the application and market, especially when used in areas such as food packaging, medicine, industry, or electronics protection. Compliance with these standards ensures that the desiccant is safe, high-quality, and suitable for its intended use.

Silica gel meets numerous international safety standards, including REACH, CLP, FDA, DIN 55473, and ISO standards, provided it is correctly manufactured and labeled. Only indicator-free, certified silica gel is permitted for use in food packaging, medical devices, or critical industrial areas. Users should always ensure compliance with applicable regulations and the submission of appropriate safety data sheets and certificates.

Die Poresphere Silicagele der GIEBEL Desiccants GmbH sind vollständig REACH zertifiziert.

In principle, yes – pure, indicator-free silica gel can be safely disposed of with household waste after use, as it is chemically inert, non-toxic, and environmentally neutral. However, there are important exceptions and recommendations, depending on the type of silica gel used and local disposal regulations.

If the silica gel is uncontaminated, it can also be regenerated by heating. This allows for multiple sustainable use cycles and can save on disposal costs. However, users should always observe local disposal regulations, especially for large quantities or commercial applications.

One exception is blue silica gel colored with cobalt(II) chloride. This is clearly classified as a hazardous substance and must be disposed of as special waste according to national legislation. Our portfolio consists exclusively of cobalt(II) chloride-free products.

Yes, Giebel Desiccants GmbH holds a valid REACH certification and therefore meets all necessary requirements for the import and trade of silica gel CAS 7631-86-9.

The REACH Regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals) has been in force in the European Union since June 1, 2007. This comprehensive EU chemicals regulation regulates the manufacture, import, and use of chemical substances – such as silicon dioxide (SiO₂) CAS 7631-86-9. If more than one ton of silicon dioxide is imported into the EU per year, special requirements must be observed:

- We ensure that our silica gel products are registered according to REACH and can be used safely:

- We provide complete, REACH & CLP compliant safety data sheets (SDS).

- We support downstream users (e.g. processing companies) in secure use.

- We ensure transparency in the supply chain and fulfill our information obligations.

Packaging Units

Our silica gels are available in various packaging sizes. These are generally:

- 250g, 500g

- 1kg, 4kg, 20kg, 25kg, 150kg