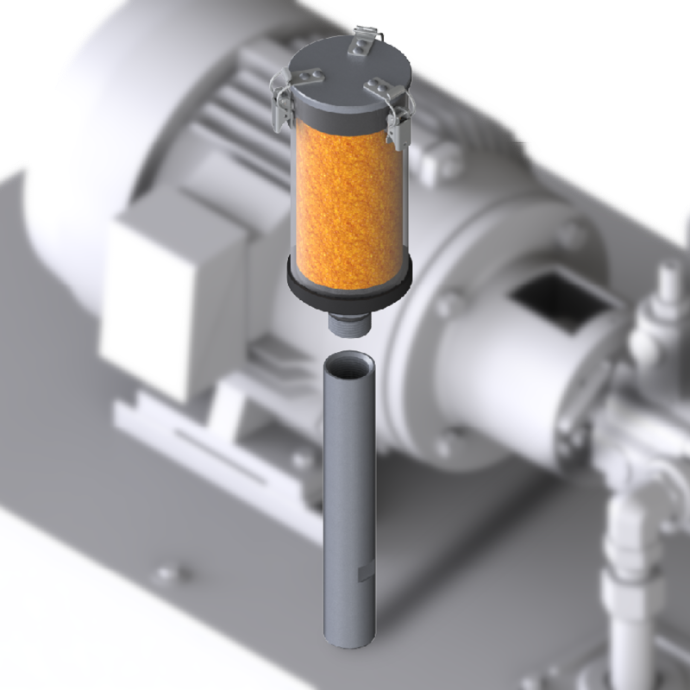

Silica gels & molecular sieves: Provide dryness where moisture causes problems.

Desiccants protect systems, moisture-sensitive goods & electrical components from contact with water.

BUY ONLINE PORESPHERE SILICAGELE VERGLEICHEN CAGESPHERE MOLEKULARSIEBE VERGLEICHEN

No corrosion, no moisture damage.

Desiccants are porous solids that reliably absorb excess moisture, thus protecting products from moisture damage. Whether in machinery, electronics, laboratory applications, and much more – they ensure consistent dryness and extended shelf life.

No corrosion on machines & electrical components

No moisture damage to appliances, tools & art during long storage periods & transportation routes

Efficient drying of process gases & food products

Wie funktionieren Trockenmittel?

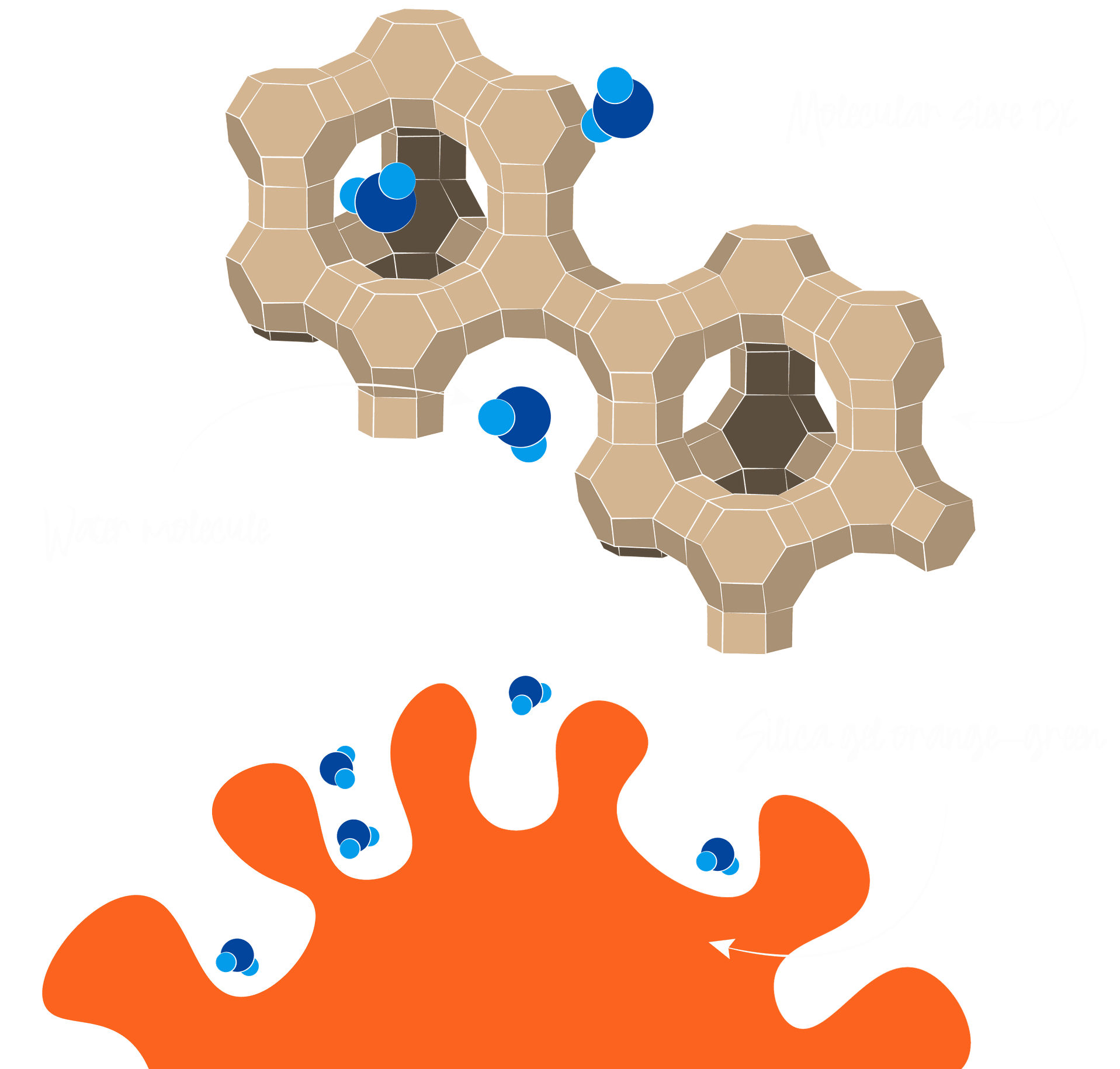

Mechanism of action

Desiccants bind water vapor to their porous surface.

A physical process that reliably reduces humidity in closed systems, thus preventing corrosion, mold, and quality loss.

Applications

Whether in the pharmaceutical, electronics or energy industries, as well as in the machinery and logistics sectors:

Desiccants protect your products from unwanted moisture during storage and transport.

Silica gel with its broad pore structure is used wherever universal moisture control is required.

Molecular sieves, on the other hand, can adsorb smaller molecules in a particularly selective manner thanks to their narrow, defined pores - ideal for highly specialized drying processes.

Was ist der Unterschied zwischen Silicagel und Molekularsieb?

Short overview

Echte Allrounder:

PORESPHERE Silicagele

Good drying performance

Can be used at temperatures up to 100°C

Can be used at humidities above 10%rh

Available with color indicator

Starke Trocknung:

CAGESPHERE Molekularsiebe

Strong drying performance

Can be used at temperatures up to 250°C

Can be used in all humidity levels

Can filter other substances in addition to water

Small but powerful:

Desiccant bags

Ideal as packaging inserts

Available with color indicator

Feature | PORESPHERE Silicagel | CAGESPHERE Molekularsieb |

Pore size | Wide spectrum - versatile | Narrow pores – very selective |

Adsorption spectrum | Universal moisture binding | Specific adsorption of small molecules (e. g. water, CO₂, gases) |

Ideal for | General dry keeping in machines, containers, packaging, etc. | Precise drying and gas purification in laboratory and industry |

Typical area of application | Machinery, equipment, pharmaceuticals, electronic packaging and shipping | Petrochemicals, gas drying, laboratory gases, analytics, plastic granulate drying |

Color indicator available | Yes - depending on the version | No - without indicator |

Sustainable Reuse | Regenerable through heating | Regenerable through heating, higher temperatures needed |

Wo werden Trockenmittel verwendet?

Anwendungsbeispiele kompakt:

3 steps to effective drying.

1

Get free advice & find the right desiccant

2

Determine packaging size

3

Effectively dry & protect goods & systems

Noch Fragen? Wir kümmern uns um Sie & Ihre Produkte!

REQUEST A CALL BACK NOW

Every year, our customers protect their machines and products with over 80,000 kg of silica gel & molecular sieve and prevent 26,400 liters of water from coming into contact with sensitive materials.

We are REACH-certified.

Giebel Desiccants GmbH is a member of the joint registration under number 01-2119379499-16-0401

Our promise

We stand for transparency, responsibility, and quality. As a REACH-compliant company, we actively support our customers in using silica gel products safely and in compliance with the law. Trust in tested chemicals and a transparent supply chain—for your safety.

Import of large quantities

Silicon dioxide is a versatile substance that is used in numerous products – from desiccants (silica gel) to various industrial applications. Special requirements must be observed when more than one ton of silicon dioxide is imported into the EU per year..

ECHA verification

Companies that manufacture or import chemicals must register these substances and submit information on their properties, use, and risk management measures to the ECHA.

FAQ zu Trockenmitteln.

Basics and functioning.

Desiccants are porous solids that bind moisture from gases or liquids through physical adsorption. Well-known mechanisms include the Van der Waals forces in porous materials (silica gel) or the selectivity through crystal pores (molecular sieves/zeolites).

Physical adsorption (physisorption) is reversible and temperature-dependent - the molecules adhere to surfaces. In contrast, a chemical reaction (chemisorption) forms strong bonds and is often irreversible as a result.

For desiccants, physisorption without the incorporation of chemical compounds is desirable, as this allows regeneration to the original state after saturation and thus the reuse of the material.

Important indicators for Desiccants are:

- Adsorption capacity (g H₂O/kg at defines rF/Temperature)

- Adsorption isotherm

- Speed/kinetics

- Bulk density

- Specific surface (m²/g)

- Pore size

Desiccants are distinguished into main groups:

- Silicagel (SiO₂-Amorph) (PORESPHERE)

- Molekularsiebe/Zeolithe (3A, 4A, 5A, 13X) (CAGESPHERE)

- Charcoal

- Aluminum oxide (Alumina)

Furthermore, a distinction can be made between:

- Pore size (fine/wide)

- Indicator color

- Particle size

- Field of application (packaging, process, gas treatment).

Selection for the application case.

For electronics and storage, indicator silica gel (e.g. orange-green) in suitable bags or cassettes is the best choice. It offers a good balance of adsorption capacity and handling - especially due to the color indicator, which reliably indicates the saturation of the dry beads with water.

PORESPHERE A INDIKATOR OG (orange - grün) PORESPHERE A INDIKATOR OF (orange - farblos)

For demanding gas tasks (selective dehumidification, low residual moisture) molecular sieves (zeolites) are often more suitable. They offer high selectivity and precisely defined pores. 13X for broad adsorption, 4A/5A for specific molecular sizes.

If high selectivity, low residual moisture or separation by molecular size is required (e.g. drying of ammonia, CO₂ removal), molecular sieves should be used.

Silica gel is often more cost-effective and robust in fluctuating conditions and standard applications where moisture needs to be removed.

Calculate the cost per cycle = material cost / (number of regeneration cycles × adsorption capacity per cycle).

Also consider the energy costs of regeneration, efficiency losses, replacement and disposal costs.

Handling and storage.

Store in airtight, dry place at moderate temperature; open packages only when in use. Use sealed containers and vacuum packaging for long-term storage.

- Indicator color change (for indicator types)

- Measurement of residual moisture in the protected product

- weight gain

- SINTEF/Labortests

- For industrial adsorbers: pressure drop, humidity at outlet.

Regeneration and disposal.

Generally, regeneration can be achieved by heating in an oven. The appropriate temperature depends on the specific product variant. As a rule, silica gel is regenerated at around 120-150°C and zeolites at 200-350°C. For more detailed information, please refer to the Technical Data Sheet, which contains all relevant information on regeneration.

Many desiccants allow for dozens to hundreds of cycles. In detail, the lifespan depends on abrasion, contamination, and thermal stress.

During testing, colorless silica gel lost about 20% of its maximum capacity after 100 regeneration cycles at 150°C. This is due to wear and tear on the material, as the specific surface area and also the pore volume of the granules decrease with continuous use.

Zeolites or molecular sieves are extremely resistant to regeneration due to their crystal structure and could theoretically be regenerated almost indefinitely. However, for this to happen, the material must remain free of carbon residues, and high temperatures and increased water vapor pressure must be avoided. Otherwise, damage to the material can also occur here.

Drying agents can usually be disposed of without any problems in household waste, as they are chemically inert, non-toxic, and environmentally neutral. However, there are important exceptions and recommendations, depending on the type of silica gel and molecular sieve used and on local disposal regulations.

If the desiccant is not contaminated, it can also be heated and thus regenerated. This makes several sustainable use cycles possible and disposal costs can be saved. However, especially in the case of large quantities or commercial use of the drying beads, users should always observe the local disposal regulations.

An exception is blue silica gel, which is colored with cobalt(II) chloride. This is clearly classified as a hazardous substance and must be disposed of as hazardous waste in accordance with national legislation. Our portfolio consists only of products that are free of cobalt(II) chloride.

Security and certifications.

Dry silica gel and zeolites are generally not toxic, but can cause possible dust irritation. Always refer to the safety data sheet provided to ensure complete safe handling of the desiccant.

Desiccants are subject to specific safety standards, norms and legal requirements depending on the application area and market, especially when used in areas such as food packaging, medicine, industry or electronics protection. Compliance with these standards ensures that the desiccant is safe, of high quality and suitable for the intended use.

Our silica gel meets numerous international safety standards. We are officially REACH certified by the ECHA (European Chemicals Agency) as a company for the import of silicon dioxide (CAS 7631-86-9) in large quantities. Only indicator-free, certified silica gel is permitted for use in food packaging, medical devices or critical industrial applications. Users should always ensure compliance with applicable regulations and the submission of appropriate safety data sheets and certificates.

REACH registration number: 01-2119379499-16-0401

The safety data sheets are provided by us for all our products and are accessible via our website.

DATENBLÄTTER PORESPHERE SILICAGEL DATENBLÄTTER CAGESPHERE MOLEKULARSIEB